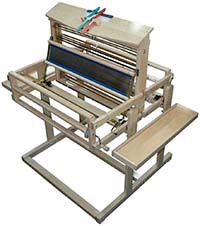

The Voyageur is simply the highest quality, most functional table loom on the market today. Originally a single narrow loom designed for the travelling weaver to take to shows, demonstrations and conferences, the product line has expanded to include multiple different versions to meet every handweaver's needs. It is an excellent loom for both beginners and experienced weavers alike, delivering full multi-shaft functionality for complex weaves in a light, small package, folding to allow easy transport and/or storage. There are now a total of 8 different versions of the loom available in 3 different weaving widths.

| MODELS | FEATURES | PRICES/SPECIFICATIONS | OPTIONS | DOCUMENTATION |

There are 3 basic Voyageur models:

|

|

|

High Quality Materials - All Voyageur Looms are made primarily from hardwood and metal giving them a very solid feel and the durability and strength required for the physical forces that occur during handweaving. The only plastic parts are washers and the fixed guides for the lever cords. Unlike other looms, Leclerc does not use elastic bands and plastic gears and pulleys for moving parts that have to be replaced when they fail. The wood is beautifully finished showing off the grain, making them fit the decor of any living space and proving that function and beauty aren't mutually exclusive. The focus on quality materials is why so many Leclerc looms are still in use almost a century after they were manufactured!

Beautifully Levered - All Voyageur Looms have 4, 8, 12 or 16 front mounted levers that can be easily activated with either hand and which operate smoothly using a unique magnetic locking mechanism that eliminates noise. The wooden handles are stained in beautiful colours to differentiate them from each other and are easy to access on the top of the castle vs looms which require the weaver to reach over or around the beater mechanism. The cords that connect the levers to the shafts are short and direct vs the complex spaghetti connections of pulleys and cables found on some looms. This makes them easy to adjust from the top of the loom if required. Normally Shaft 1 is on the right side, but this can be reversed so it is on the left if preferred (indicate on order). The Voyageur looms all produce a nice clean shed with minimal effort by the weaver.

Shafts, Shafts and More Shafts - The Voyageur loom is designed to address every weaver's requirement and comes in 4, 8, 12 and even 16 shaft configurations to allow the simplest to the most complex of patterns to be woven. The 8 different models in the Voyageur family are made with the same Leclerc high quality as all the company's looms.

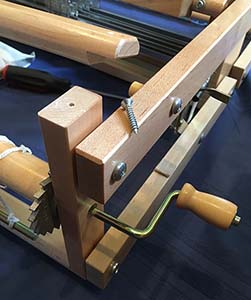

Durable Warp/Cloth Beam Hardware - Like the company's larger floor looms, the Leclerc Voyageur table looms use metal components for their take-up motion and brake mechanisms on the cloth and warp beams. The beam handles are shaped to be easier to grip and apply force to. As well as allowing higher tension on the warp threads, the Voyaguer system does not use lower cost plastic parts for the ratchets, pawls and handles that break or wear. Because the weight of the pawl keeps it locked in place, it does not have to have a special "clicker" mechanism in the pawl that flexes causing it to wear or break over time. Proof of this Leclerc advantage is the number of times customers ask us if Leclerc metal ratchet wheel, pawl and crank handle parts can be used to upgrade other manufacturer's looms!

The Leclerc metal handles extend from the loom and are designed to allow the weaver to easily grab and exert force to rotate the warp beam to tension the warp and then increase the tension slightly to make it easy to release the pawl when advancing the warp. This is a problem with some other table looms with low profile plastic warp/cloth beam handles. Because they are hard to grip one loom manufacturer sells an optional $25 wood extension that fits over the loom's plastic handles to provide the weaver with a proper handle. As well as extra cost, this adds complexity and time to each warp advance, especially if it has to be moved between the warp and cloth beams each advance! Definately not a "Handi" solution!

Easy Folding - While most table looms fold up for transport and storage, the Leclerc Voyaguer looms are probably the most straight-forward. Instead of the Voyageur's simple "undo the 4 red screws and raise the front and back beam" directions, many table looms require a set of instructions to fold the loom that resemble those used to put together a piece of Ikea furniture! Complex instructions for other looms like "undo knobs A, B, C and D, swing main castle forward to a 45 degree angle, remove pin F and rotate bar N while holding beater supports L and M out of the way" are quickly forgotten so the loom never gets folded up by the owner. To see how easily the Voyageur loom folds up, click here. The Voyageur looms all reduce in size to occupy a compact amount of space while the 9 1/2 inch Voyageur when folded is even small enough to meet most major airline's requirement for carry-on baggage (verify with the specific airline).

The Voyaguer looms sit upright while folded with the front and back beams lifting up so the folded loom sits on the same base as when it is unfolded and in operation. As well as taking up less room than the looms that "collapse" the castle down onto the frame, the Voyaguer protects the warp threads and finished cloth by lifting them up and away from the floor. The "Collapsing Castle" looms let the warp/cloth touch the floor if they are left leaning against a wall to for stability and to reduce their footprint. The 9 1/2 and 15 3/4 inch Voyageur looms also come with a durable denim carrying bag that protects the loom and warp when travelling or not in use.

Heddle Flexibility - Like all Leclerc looms, the Voyageur does not restrict the weaver as to what type of heddles are used. The looms can be ordered with either Texsolv or Inserted Eye wire heddles and can be easily switched in the future if the owner changes their mind. The Voyageur is able to do this because the loom has actual metal shaft frames with heddle support bars and not just simple wooden Texsolv heddle support bars. The ability to easily remove the heddle support rods holding all the heddles from the metal shaft frame, lie them down on a table and comfortably adjust quantities on each, also makes it easier to transfer heddles between shafts without disassembling the loom or requiring the weaver to have 3 hands to do it while on the loom.

Longer Warps - The length of a warp that can be comfortably woven on a loom is dependent on the thickness of the cloth/warp threads, the amount of room needed by the warp separators being used and the clearance of the beams they are wound upon. Many looms that use the "Collapsing Castle" means of folding for storage reduce their folded size by lowering the frame the warp and cloth beam are attached to. Unfortunately, this approach limits the vertical clearance between the beams and the loom frame/warp and reduces the size of the warp that can be wound on.

Because the Voyageur has a different folding mechanism, it is built with a tall 8 1/2 inch high frame. This means the warp/cloth beam can expand in size to a little more than a 6 1/2 inch diameter without touching the frame. An example of the size of warp that can be supported is shown in this picture. Note that this space even also allows the 24 inch Voyageur to be configured with a special beam with rakes for sectional warping.

One other loom manufacturer recognizes this problem and provides the ability to move the warp and cloth beams down to the frame of their floor stand, but this adds hundreds of dollars of cost, reduces the loom's portability and forces the weaver to reach down to their knees or stand up from the loom to advance the warp and/or release the brake. The lowered cloth beam also means the lowered warp may come in contact with the weaver's knees.

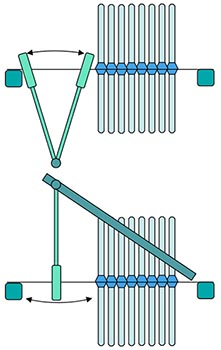

A Better Beater - When designing a loom, the beater design is an important consideration. Normally one end of the beater swords attach to the loom at a pivot point that allows the reed to travel in an arc at the other end of the swords. The longer the swords, the flatter the reed's arc and the more perpendicular it is to the warp threads. Because of the arc, the point at which the warp threads will go through the reed will move up and down a bit as the beater moves through it's swing and the reed must be tall enough to accommodate this.

Because the Voyageur has a tall frame, there is enough room to implement a underslung beater by attaching the beater swords to the base of the loom frame. However because "Collapsing Castle" looms have such a short frame, they do not have the room for an underslung beater and are forced to mount a set of "antler" like supports sticking up from the loom to suspend a hanging beater from to get a flat arc. The Voyageur's clean look provides the weaver with a less awkward beater implementation and makes it easier to see what is going on in the loom. The weaver also does not have to reach through the beater mechanism to flip the shaft levers. Also, when threading the heddles from the front, loosening 2 screws at the top of the beater allow the reed to be easily moved out of the way so the Voyageur is just as easy to thread back-to-front as it is front-to-back (see pictures here).

Another big advantage of the underslung beater is that gravity causes it to sit back against the warp threads or up against the castle without being held by the weaver. Hanging beaters sit at the bottom of their arc which means that the weaver has to use one hand to push the beater out of the way, while throwing the shuttle. The picture to the right shows the rest position(s) of each of these beater types. One loom manufacturer with a hanging beater has acknowledged the problem by adding an elastic band to pull the beater toward the castle and out of the way which adds both a potential failure point and extra work for the weaver when beating the weft. Other loom makers position the beater closer to the castle reducing the effective beating area or have to add some kind of complicated latch mechanism to keep the beater out of the way. The Voyageur beater is perfectly positioned and just uses gravity to stay out of the weavers way!

In addition to the basic beater design functionality, Leclerc's unique Swinging Beater option uses a unique pivoting design to help to reduce the frequency of warp advances. See below for more information.

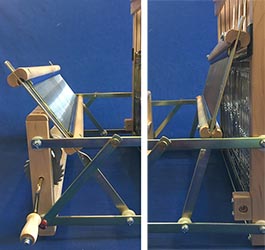

Swinging Beater - Because of the shorter distance between the front breast beam and castle on a table loom, warp advances are required more frequently than on a floor loom. A Swinging Beater option is available for Voyageur looms that optimizes the use of this smaller space, allowing the weaver to keep the reed vertical to the warp threads regardless of the position of the fell line. This allows the reed to get very close to the castle and breast beam allowing for a wider beating range.

The Swinging Beater, by keeping the reed perpendicular to the warp threads also ensures that the maximum amount of force is applied on the weft threads.

The Swinging Beater can be ordered as the standard beater on a new loom or as an option. The beaters are easy to switch, even while the loom is warped. The top Batten lifts off allowing the Reed to be easily changed and a Raddle to be installed in the beater for warping. Watch the attached Swinging Beater video to see it in action!

Note that unlike the regular beater for the 24 inch Voyageur, the Swinging Beater does not include or support a Shuttle Race. To see both beaters in more detail, click on the picture to the right.

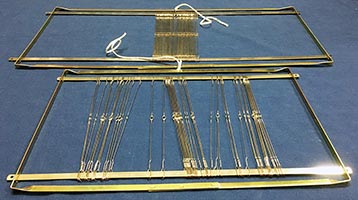

Shaft Frames - Like their larger floor looms, Leclerc designed their looms with actual shaft frames. The Shaft Frame is a rectangular metal frame with holes for the heddle support rods that the heddles are fed onto. Because this is more expensive to do, many lower cost looms skip the shaft frame and just use the horizontal heddle support bars and attach them together with a vertical bar on each side.

One of the advantages of the Shaft Frame approach is that the shaft can be lifted by a lever with a simple cord attached to the top of the shaft frame in the center. Without shaft frames, two cords have to be used, one for each side of the upper heddle support bar and the cords have to be routed two each side of the loom through a spaghetti maze of guides and pulleys which are normally hard to get at. In addition, the cords need to be matched in length to make sure both sides are lifting evenly and both must be adjusted to get the shaft to lift to the proper height. With the Voyageur shaft frames, a single short Texsolv cord for each shaft is routed down in a very simple straightforward path as pictured to the right. The Texsolv loop cord length is very easy to adjust (simply switch the loop the screw on the lever attaches to) and there is no need to spend time untying and tying knots at the correct length or making cord adjustments to get the loom to work properly. The cords also can't come off the pulleys and guides because none are used.

The shaft frame also adds mechanical support to the heddle support rod allowing the rod to be thinner which is why wire heddles can be used as well as Texsolv. The shaft frames also keep the heddles in place so they can be slid out and placed on a table to make transferring and adding heddles easier. The heddle support rods have holes at each end to tie a string to, so heddles can be added or removed while keeping them in order and aligned properly.

Because the Voyageur looms use rigid shaft frames, the shafts rise and lower with a simple movement of the lever and with no other assistance, regardless of the type of heddles used. Some other looms without shaft frames actually need to install a bunch of elastic bands under the shafts to pull them down! This creates a reliability issue as these cheaper parts age, fail and need to be adjusted or replaced.

Lots of Extras! - All Voyageur looms come with a larger number of heddles (see chart below) than most other table looms (double what some other manufacturers provide), A Heddle/Reed hook, heddle transfer bars, lease sticks, assembly instructions, all tools required, a Stainless Steel Reed (12 dent unless specified otherwise) and even a specially designed low profile boat shuttle made of Cherry. The 24 inch Voyaguer regular beater also comes with a shuttle race to support the base of the shed (not available on the Swiging Beater). The 9 1/2" and 15 3/4" Voyageur looms even come complete with a custom made denim carrying bag that includes a pouch for tools.

Options - As well as the Swinging Beater and choice of Heddle style, a number of options are available including a Double Warp Beam and a number of options to turn Leclerc table looms into floor standing models. These include a Folding Table for the 15 3/4 inch model is available which includes side shelves. It quickly collapses flat allowing it to be easily transported with the loom.

A Heavy Duty Floor Stand for the 24 inch model can also be ordered with or without side shelves. It's height adjustable to fit it to any size of weaver and solid to avoid the tipping or movement while weaving that plague the lower cost and simpler "X" frame type folding stands that some loom manufacturers still use.

Both of these floor mounting options allow quick installation and removal of the table loom without the need to move warp/cloth beams between the stand/table and the loom. Also, because the cloth/warp beams do not have to be moved, winding on and advancing the warp is the same and the weaver is not forced to reach down to their knee level or stand up and walk around the loom to simply release the brake and/or advance the warp! Even more importantly, the cords connecting the levers to the shafts do not have to be adjusted to different lengths when it is used on a table or on the floor stand. Simply undo the 4 clamps that hold the Voyageur loom to its stand, lift it off and sit it on the table and continue weaving!

The 24 inch Voyageur looms can also be configured with a Sectional Warp Beam to expand the loom's warping functionality. This warp beam installs in few seconds and comes with a temporary breast beam to allow the weaver to mount the Leclerc Tension Box on the loom.

The levers on the Voyageur looms are set with #1 (shaft closest to the weaver) on the right side but can be reversed in the factory if specified on the order. Also, the weaver can specify a different reed than the standard 12-dent one included. Setting up the loom is as simple as unpacking it and threading the heddles on to the shafts and to make things easy, all tools needed are included.

Friction Brake - The 9 1/2 and 15 3/4 inch Voyageur models use a ratchet/pawl system for the warp beam brake. This can be released by the weaver while seated by reaching back along the right side of the loom to the warp beam.

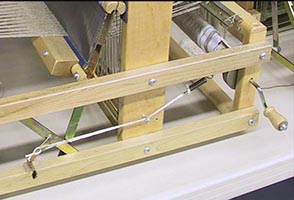

The 24 inch version of the Voyaguer, like most wider table looms, has a deeper frame which would make this difficult. Instead of the ratchet/pawl system, it includes a full friction brake which allows infinite warp beam positioning to minimize warp advances. The friction brake can be engaged and released using a lever at the front of the loom allowing the weaver to remain seated which is a significant advantage over competitive looms. (Friction Brake Video).

The 24 inch Voyageur also includes Leclerc's unique Warp Beam Advance Control mechanism that prevents the warp beam threads from unravelling when the brake is released.

Ease of Warping - The Voyageur is a dream to warp and there are no rules. Whether you want to warp front-to-back or back-to-front, it's your choice! As well as being the best loom to weave with, a lot of thought has been put into making the Voyageur the easiest to warp.

There are no hanging beater "antlers" sticking up to get in the way of the weavers arms while they thread the heddles or sley the reed. The levers are up at the top of the castle and out of the way. Undoing two screws on the top of the beater allows the reed and beater to be removed and placed out of the way. Heddles can be Wire or Texsolv; whichever the weaver finds easier to use. The Leclerc Raddles are designed with the same form factor as their reeds allowing them to be temporarily installed in the regular beater during warping.

Removing two screws allows the front or back breast beam to be removed to make it easy to tie to the warp or cloth beam. On some looms the beams are the only frame support and the loom will collapse if they are removed so if they are in the way, the weaver just has to work around them. On the Voyageur, holding the cloth/warp beam in one hand and turning the crank handles backwards allows them to be unscrewed to easily pop the cloth/warp beams out if they are in the way.

Leclerc even provides an optional Sectional Warp Beam for the 24 inch Voyageur looms which comes with a special breast beam that enables the Leclerc Tension Box to be attached to sectionally warp the loom. That's not something found on other table looms!

Note that when used on the 24 inch loom, the Sectional beam reduces the weaving width slightly to 23 inches.

Support - No table loom on the market has better support than the Voyageur! Camilla Valley Farm provides support for all the Leclerc products we sell and even extend the manufacturers warranty by a year. We work directly with Leclerc on a daily basis and if you have questions we answer them and do not simply direct you to the manufacturer. Support is more difficult for loom manufacturers outside North America who often have to rely on in intermediate distributor. For questions and problems, the dealer often has to ask the distributor who then has to contact the manufacturer on the other side of the world often causing the original question to be distorted and delayed.

As well as stocking most of the products Leclerc has in their catalog (and a lot that they don't) we receive shipments from the company each and every week while smaller dealers may experience delays until they have a large enough order. As a sign of how well Leclerc looms are supported, we regularly provide repair parts for Leclerc looms made during the last 80 years.

Shuttle Race - Like most table looms, the Voyageur uses a "Jack" mechanism to create the shed for the shuttle to travel through. This means that every pick, 1 or more harnesses lift a set of warp threads to form the top of the shed while leaving the rest of the warp to form the base. Because the raised warp threads have to travel a longer route from the back to front beam they are under a higher tension than the warp threads at the base. This is not the case in Counterbalance or Countermarche looms as both the upper and lower warp threads are under tension.

A common problem, especially on wider jack looms, is that the looser warp threads at the base do not do as good a job of supporting the base of the boat shuttle as it travels through the shed from side to side. Many weavers have experienced the frustration this produces when the tip of their boat shuttle catches one of the lower threads and either stops in the middle of the shed, causes a weaving mistake and/or drops through the warp onto the floor. On narrow looms where the shuttle length is close to the loom weaving width, the weaving process is more handing the shuttle back and forth so it is not a problem but on wider looms it makes the throwing motion used to pass the shuttle through the wider shed more tricky.

The regular beater on the 24 inch version of the Leclerc Voyageur has been designed to solve this problem in the same way the company handles it on their much wider floor looms. A "shuttle race", which looks like a wooden shelf, is built into the standard beater (not the swinging beater) to provide support to the base of the shed and creates a track for the shuttle to travel. This allows wider fabric to be woven faster, easier and with fewer mistakes when compared to other table looms!

More Value for the Money - As a North American loom manufacturer, Leclerc has the benefit of not having to add a second level of distribution between themselves and their retail stores. Most of the other loom manufacturers, as well as having to add the price of International shipping and import costs to their looms, must also include the cost of a North American importer who buys from them, imports the looms and then sells them to the dealer adding another level of markup. This results in higher prices for the loom or less money being put into the materials used to make them affecting quality.

To get their prices down, some loom manufacturers remove items that then have to be purchased by the weaver separately. Some looms actually come with half the number of heddles that are required, don't include a boat shuttle (or replace it with a low cost stick shuttle), don't include a reed/heddle hook and some even charge extra for a low quality version of the durable carrying bag that is included free with the 9 1/2" and 15 3/4" Voyageur models.

Get Weaving Faster! - While some manufacturers ship their table looms as a bunch of parts that the buyer must use to "build" the loom, the Voyageur loom's unique folding design enables it to be safely shipped almost fully assembled.

After unpacking the 15 3/4 inch Voyageur from its shipping box, once the warp and cloth beams are moved into position and the heddles are added to the shaft frames, the loom is pretty well ready for weaving as shown in the picture to the right.

The 24 inch Voyageur model requires a few more steps but the assembly process is very simple as shown here.

No Metric Headaches - 12 dents per inch equals 4.724 dents per cm -- 100 yards per pound equals 49.605 metres per kilogram -- if you are weaving 24 epi and your metric raddle has 0.5 cm spacing put 7.72 threads in each slot.

As a North American manufacturer, Leclerc recognizes that while the Metric measurement system is prevalent in other parts of the world, handweavers in North America generally practice their craft using inches, feet and yards rather than millimeters, centimeters and meters. Project planning, calculations and the warping process can be complicated enough without adding the need to convert units and adapt patterns to a different measurement system.

With that in mind, Leclerc Reeds are calibrated in dents per inch, Leclerc Raddles divide the warp into 1/2 inch groups, Sectional Warping Beams allow warp to be wound 1 or 2 inches at a time and Leclerc Counters for their Spool/Bobbin Winders and Tension Box let you know how many yards have been wound. Even the weaving widths of the various models of Nilus II are described in inches ... and as a little bonus, give you a few more inches than their metric counterparts!

Converting everything to and from metric and adapting to metric spacing on reeds and raddles may not seem like a big issue, but any little extra step when repeated over and over increases the chance of mistakes occuring and can take some of the joy out of weaving.

Tools and Accessories

While the most important component of handweaving is the weaving loom, a number of other tools and accessories are required to create a warp, put it on the loom and then to weave a fabric with it. There are also a number of different approaches and special requirements for different types of fabric.

As well as a wide variety of weaving looms, Leclerc produces all of the tools that are required by the handweaver. They have been designed to work together and to allow the weaver with the maximum degree of flexability.

See our Weaving Tools Checklist for a description of the warping and weaving process to understand which tools are required at each stage and why.

If you are new to weaving, this guide gives you a very quick summary of what is involved in preparing the loom and weaving the fabric. It helps ensure that you have the right tools at the start to be able to work through the process without interuptions while you source the tools you need to be able to continue.

The ordering information as well as dimensions and weight of the Voyageur loom models are listed below:

| Loom | 9 1/2" (24 cm) | 15 3/4" (40 cm) | 24" (60 cm) | ||||||

| Shafts | 8 Shaft | 4 Shaft | 8 Shaft | 12 Shaft | 4 Shaft | 8 Shaft | 12 Shaft | 16 Shaft | |

| Part Number |

Regular Beater | 2120-0009 | 2120-0416 | 2120-0016 | 2120-1216 | 2124-0424 | 2124-0824 | 2124-1224 | 2124-1624 |

| Swinging Beater | 2120-0009s | 2120-0416s | 2120-0016s | 2120-1216s | 2124-0424s | 2124-0824s | 2124-1224s | 2124-1624s | |

| Pricing | $1,237 CDN $1,138 US |

$1,113 CDN $1,113 US |

$1,237 CDN $1,138 US |

$1,579 CDN $1,452 US |

$1,492 CDN $1,372 US |

$1,665 CDN $1,532 US |

$1,815 CDN $1,670 US |

$2,269 CDN $2,088 US |

|

| Heddles (#) | 300 | 400 | 400 | 500 | 600 | 600 | 600 | 600 | |

| Width | Weaving | 9 1/2" (24 cm) | 15 3/4" (40 cm) | 24" (61 cm) | Overall | 13" (33 cm) | 19" (48 cm) | 28 1/2" (72 cm) | |

| Depth | Open | 21" (53 cm) | 19 3/4" (50 cm) | 21" (53 cm) | 22 1/2" (57 cm) | 26 3/4" (68 cm) | 27 3/4" (70 cm) | 30" (76 cm) | 31 1/2" (80 cm) | Folded | 9" (23 cm) | 9" (23 cm) | 9" (23 cm) | 11 3/4" (30 cm) | 11 1/4" (29 cm) | 12 1/4" (31 cm) | 14.5" (37 cm) | 17" (43 cm) | Height | 20" (51 cm) | 21" (54 cm) | 20 3/4" (53 cm) |

| Weight | 16 lb (7.25 kg) | 12.5 lb (5.7 kg) | 20.5 lb (9.3 kg) | 25 lb (11.3 kg) | 25 lb (11.3 kg) | 29 lb (13.2 kg) | 32 lb (14.5 kg) | 35 lb (15.9 kg) | |

|

|||||||||

Every Leclerc Voyageur Table Loom ordered from Camilla Valley Farm comes complete with the following extras to get you up and weaving immediately:

|

These options can be added to your order to expand the functionality of your Voyageur loom.

| Voyageur Options | Ordering Information | |||

| 9 1/2" | 15 3/4" | 24" | ||

| Texsolv Heddles (instead of inserted eye heddles) |

Specify on Order $0.00 |

|||

| Raddle | N/A | 6258-1000 $40 CDN $37 US |

6258-9024 $65 CDN $60 US |

|

| Additional Reeds (one included) |

4-15 Dents/inch |

$84 CDN $77 US |

$84 CDN $77 US |

$128 CDN $117 US |

| 16-25 Dents/inch |

$96 CDN $88 US |

$96 CDN $88 US |

$145 CDN $134 US |

|

| Double Warp Beam Option (2nd Warp Beam and frame) |

N/A | 6432-1001 $475 CDN $437 US |

6432-1100 $496 CDN $457 US |

|

| Sectional Warp Beam | N/A | 6443-1500 $516 CDN $475 US |

6443-1100 $516 CDN $475 US |

|

| Swinging Beater Option | 2120-0995 $163 CDN $150 US |

2120-00916 $163 CDN $150 US |

2120-0924 $193 CDN $175 US |

|

| Note: No charge if ordered instead of regular beater | ||||

| Folding Table | N/A | 6312-2000 $336 CDN $309 US |

N/A | |

| Loom Stand with 2 Side Shelves |

N/A | N/A | 88800-0416 $718 CDN $550 US |

|

| Loom Stand without Side Shelves |

N/A | N/A | 88800-0417 $660 CDN $508 US |

|

Check out our Manual Section for downloadable assembly instructions for this and other Leclerc looms and weaving accessories. Information is also provided on upgrades and accessories. If you are not sure which Leclerc loom you own see our Leclerc Loom Guide to help identify the model.

|

CAN'T DECIDE? Contact us for help in answering questions about this loom, getting information about others or for help recommending a loom matched to your weaving level and needs. See our Leclerc Loom Comparison Chart for more help in deciding which loom is right for you. |

|

How to Order: Orders may be placed using our secure Online Order Form (this form should open in another window). Click Here for more information on how to place an order as well as our terms and conditions. Payment/Currency: Payment can be made using VISA or Mastercard, Cheque or Money Order in US or Canadian funds. US credit card purchases are billed directly in US funds eliminating any foreign currency conversion charges by the credit card company. Product Directories If you are looking for other items on our website, try using our product directories to quickly find what you are looking for! Our products are grouped as follows: Weaving/Spinning Product Index Books, Magazines & Videos. |

Price/Shipping Quote? If you would like an exact quote for any items complete with shipping costs, please call or email us at nmanners@camillavalleyfarm.com with you location and we will provide this. Gift Certificate If you are looking for a gift for a Knitter or Weaver and can't figure out what they want, a Camilla Valley Farm Gift Certificate is an excellent way to ensure you get the perfect gift! We can also email gift certificates if you are running out of time! Latest News/Updates Keep up to date with what is new at Camilla Valley Farm by following us on Instagram! (Click on the logo below)  |