Large Clean Sheds!

All the Artisat loom models have large sheds making it easy to throw a shuttle through regardless of which size is used. They all have shuttle races in the beater mechanism but the design of the looms are optimized to provide a clear large path for the weaver to insert weft thread regardless of whether they are using a boat, stick, rag, end feed or flying shuttle.

|

|

|

The Amazing Shrinking Loom!

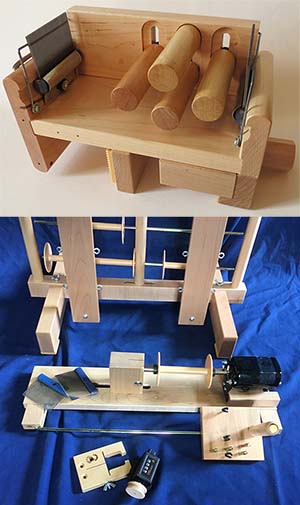

While some smaller looms have folding back beams to reduce their size, a set of unique hinges on the Artisat frame gives it an amazing ability to reduce size when not in use. These allow the front frame as well as the back beam to fold inward to shrink the loom down to a depth of 16 to 24 inches depending on the number of shafts.

The treadle set is easily removable by loosening/removing two bolts at the weavers feet and disconnecting the cords. All this can be done while the loom is warped in the the middle of a project, making it easy to hide the loom away when not in use or for transporting or when it is to be moved through a doorway.

The 4 shaft Artisat is shown folded to the left and the 8 shaft Artisat BHT version is shown to the right. To see how the loom folds up the video here demonstrates the process using the 4 shaft model. The steps required to fold the loom are shown in detail here. |

|

|

Warp Advance System

To advance the warp and move the fell line to the optimal position, a Take-up Motion Handle is located on the right side of the cloth beam, easily accessable to the weaver. A heavy duty metal pawl on the handle grips the ratchet wheel on the end of the cloth beam to rotate it and to wind the woven fabric onto the cloth beam. To lock the cloth beam in position while weaving a metal pawl attached to the loom frame stops the it from turning in the opposite direction. A wooden handle handle provides a comfortable grip and a metal bracket supports the handle in the horizontal position but does not interfere with raising the handle vertically out of the way when folding up the loom. The length of the handle provides the weaver with the leverage to easily tension the warp a few "clicks" at a time while allowing the warp beam to turn by putting their right foot on the brake treadle.

The Leclerc Take-up Motion handle is dedicated to this function and located in a comfortable position for the weaver to grasp. Some loom manufacturers reduce costs by using the warp beam crank handle to also advance the warp which means that it has to be attached to an awkward to reach position on the side of the loom that often means the weaver must interupt their rhythm by getting up and walking around to the side of the loom to grasp it to provide enough force to tension the warp or to pick it up off the floor when it falls off. In addition, the weaver must them move the crank to the warp beam to rewind the warp threads if they advance the warp too far. Leclerc also provides a Crank Handle but it is dedicated to turning the warp beam and can be left attached to it.

As well as increasing the strength by using metal, the weight of the pawl allows them to use gravity to lock in place. It also means that once a project is finished, the weaver can simple flip the two pawls up out of the way and unroll the fabric off the freely rotating cloth beam. |

|

|

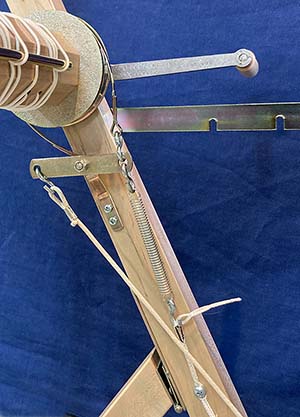

Leclerc Friction Brake

All Artisat models come with the Leclerc Friction Brake system. The brake uses a flat metal band called a Brake Circle wrapped around a steel Brake Drum on the end of the Warp Beam. Contact between the two applies a tremendous amount of force to prevent the warp beam from turning. A light touch on the wooden brake treadle by the weaver's right foot, while remaining seated at the loom, releases the tension, which allows the brake circle to increase in diameter which in turn allows the warp beam to rotate. Using steel for all the brake parts instead of wood or rope provides a stronger brake systemn as well as preventing the premature wear that might otherwise require the replacement of the brake band, drum or even the whole warp beam assembly.

The Brake Spring holds the Brake Circle tight against the drum and the tension it applies can be adjusted by shortening or lengthening the cord it uses to attach to the loom frame. A small lever by the weavers left foot can be used to hold the brake treadle down with the brake released.

The Leclerc Friction Brake coupled with Leclerc's Warp Advance Control system enables the weaver to easily apply anything from a small to a very large amount of tension on the warp threads and Leclerc's unique Warp Beam Advance Control system stops the Warp Beam from unravelling the warp threads when the brake is released.

Unlike the Ratchet and Pawl mechanism used on some looms, the Leclerc Friction Brake allows the warp beam to be locked in an almost infinite number of positions rather than those dictated by the number of teeth on the ratchet wheel. The Friction Brake also eliminates the problem of ratchet wheel teeth breaking. When a large amount of tension is applied in a Ratchet/Pawl system, releasing the brake requires the pawl to be raised up along the ratchet wheel tooth, ultimately applying pressure to the weak narrow tip of the tooth which can cause it to snap off. Leclerc converted away from this type of brake back in the 1950's but it is still being used by some loom makers.

The heavy duty oversized Steel Brake Drum and the special metal Brake Circle are much more expensive than the lower cost wooden brake drum and wire loop system or simple ratchet brake design other manufacturers use but produces a stronger, more durable, dependable and functional design which is why there are many Leclerc looms with their original friction brake still working hard after decades and decades of use!

|

|

|

Warp Advance Control System

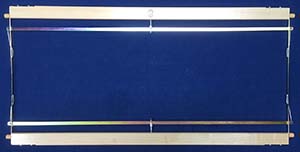

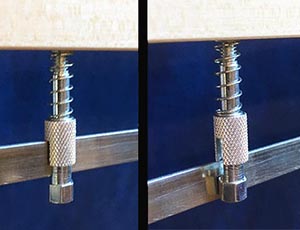

Located at the back of the loom on the left side, the Warp Advance Control system allows the weaver to add a variable amount of friction to the warp beam using a nylon screw mechanism.

This control prevents the warp beam from spinning out of control, unwinding the warp when the brake is released suddenly and is especially useful when weaving a highly tensioned warp like that used for weaving rugs.

The Warp Advance Control can be set up so that when the brake is released, the warp beam only rotates when the weaver advances the warp with the Take-up Motion Handle on the front right side making warp advances quick and easy. |

|

|

Beater/Reed Design

The reed for the Leclerc Artisat loom is installed in the Beater between two horizontal beams called the "Batten Handtree" and the "Batten Sley". These 1 3/4 inch square Maple beams hold the Reed securely in position by sitting below and pressing down from the top. The Upper Batten Handtree is fastened with wingnuts that when loosened allow it to be raised to remove or change the reed. The space for the reed is not blocked on either the right or left side so the weaver to use a reed that is longer (or shorter) than the one made for this loom width by letting the extra length stick out on either side. Because Leclerc offers a wide range of their own Carbon and Stainless Steel Reeds Artisat owners don't have to deal with the frustration of searching to find something to fit their loom.

The Artisat Batten Sley has an additional piece of wood attached to it called the "Shuttle Race". Fastened on an angle, it provides a solid base for the lower warp threads to help support the shuttle on its path through the shed. It is held on using a set of screws and can be removed if the weaver does not want to use it.

The optional Raddle Leclerc makes is designed with the same profile as the reed to allow it to be installed and held in the beater during the threading process. It can also be mounted to the front or back beams of the looms using a set of metal clips that are included.

|

|

|

Easy Shaft Removal

By removing the Castle Top, the weaver can easily just lift shafts out of the loom castle without disconnecting cables unattaching connectors.

This makes it very easy to add more heddles or directly transfer them between two shafts by lieing them down end to end on a table.

Heddle additions/removals can also be done while the shafts are on the loom. |

|

|

Leclerc Tie-up System

The Leclerc Tie-up system is designed to make the process easier. Instead of having the weaver tie knots under the loom and fine tune cord lengths, the connection between the lams and the treadles is made with fixed length Treadle Cords that are locked in place using quick release steel Treadle Hooks that are threaded through screw eyes in the treadles.

The standard Treadle Hooks lock by grabbing the first screw eye they go through and the Back-Hinge Treadles have a nylon vertical locking pin to keep them in place.

The standard treadle tie-up is shown to the right and the Back-Hingle Treadle Tie-up system is pictured to the left. |

|

|

Storage on Top

Artisat looms come with a Wooden Castle Top that provides handy storage for the weaver. When removed, the shafts can be easily lifted out to move or add heddles on a table. |

|

|

|

Shaft Frames

On a loom, the "shaft" holds a group of heddles that in turn lift and/or lower a specific set of warp threads to create the shed that the shuttle feeds the warp threads through. There are two primary ways used by loom manufacturers to construct these "shafts". Leclerc floor looms like the Artisat use a rigid rectangular "shaft frame" and then within it, provide a mechanism to support the heddles called the Heddle Support Rod. A simpler way is to use two wooden sticks called "shaft bars" and thread heddles on to them. While greatly reducing the cost to make the loom, the "shaft bar" approach brings with it some disadvantages.

Because these shaft bars have to remain rigid while fighting the warp tension to raise or lower, they have to be thick. This thickness normally limits their use to Texsolv heddles as the wire and flat metal heddle mounting holes are too small. The wider bars also reduce the effective length of the heddles. In the Leclerc shaft frame, the narrow metal heddle support rods are thin and narrow enough to use Texsolv, Wire, Inserted Eye and/or Flat Metal heddles. The shaft frame provides the rigidity necessary and removable spring hooks are used to bind the heddle support rod to the shaft frame.

On the Artisat, the heddle support rods are attached to the shaft frame on either side using Shaft Frame Spring Clips. While Heddle Support Rods do flex, they are held rigid to the Shaft Frame while weaving using a pair of Heddle Support Bar Spring Hooks in the middle of the shaft frame at the top and bottom. During the threading process, releasing these hooks removes the tension from the heddles making them easy for the weaver to move side to side. The difference in tension on Texsolv heddles with and without the Spring Hooks engaged is demonstrated in this video.

|

|

|

Upgradability

Leclerc makes Upgrade Kits that enable Artisat 4 shaft loom models to be upgrade to 8 shafts. Kits are also availble to turn 8 shaft front hinge treadle looms into Back-Hinge Treadle versions. The additional shafts allow a weaver to expand the complexity of the weave structures they can produce on the loom and the Back-Hinge Treadle option makes the looms easier to operate if they suffer mobility problems.

Contact us for more information on these options. |

|

|

No Metric Headaches

12 dents per inch equals 4.724 dents per cm -- 100 yards per pound equals 49.605 metres per kilogram -- if you are weaving 24 epi and your metric raddle has 0.5 cm spacing put 7.72 threads in each slot.

As a North American manufacturer, Leclerc recognizes that while the Metric measurement system is prevalent in other parts of the world, handweavers in North America generally practice their craft using inches, feet and yards rather than millimeters, centimeters and meters. Project planning, calculations and the warping process can be complicated enough without adding the need to convert units and adapt patterns to a different measurement system.

With that in mind, Leclerc Reeds are calibrated in dents per inch, Leclerc Raddles divide the warp into 1/2 inch groups, Sectional Warping Beams allow warp to be wound 1 or 2 inches at a time and Leclerc Counters for their Spool/Bobbin Winders and Tension Box let you know how many yards have been wound. Even the weaving widths of the various models of Artisat are described in inches ... and as a little bonus, give you a few more inches than their metric counterparts!

Converting everything to and from metric and adapting to metric spacing on reeds and raddles may not seem like a big issue, but any little extra step when repeated over and over increases the chance of mistakes occuring and can take some of the joy out of weaving. |

|

|

Sectional Warping

Most looms are designed to be warped by first constructing the warp on a Warping Board or Warping Mill. When it is complete, the weaver then winds the whole warp on the loom's Warp Beam.

This is also true for looms like the Artisat, but Leclerc designs all their looms to be easily upgradeble to Sectional Warping, which is an alternative warping method that allows the weaver to wind the warp on the Warp Beam directly from yarn Spools, 1 or 2 inches of weaving width at a time. Some weavers find this approach faster than conventional warping and it offers a lot of advantages, especially with long warps or warps for very wide looms.

To facilitate Sectional Warping on their looms, Leclerc uses an octagonal Warp Beam that can be used for conventional warping with an Apron and Warp Rods or can be converted to Sectional Warping by attaching a set of 4 Sectional Beam Rakes that divide the beam up into these 1 or 2 inch sections. The Back Beam is designed to allow their Tension Box, that maintains the tension on all the warp threads being wound on, to be mounted to. A Spool Rack sitting behind the loom is used to hold the yarn tubes and/or spools that feed the warp through the Tension Box onto the Warp Beam.

This flexibility to configure the loom for either conventional or Sectional Warping allows the weaver to increase their efficiency and expertise as their weaving requirements change.

|

|

|

Heddle Type Flexibility

Which type of heddles are better? Texsolv or Wire Heddles? Plain Wire or Inserted Eye? While each type of heddle has their advantages and disadvantages, Leclerc has designed the Artisat with the flexibility to let the weaver decide!

Because the Artisat uses shaft frames instead of simpler Heddle Bars, the weaver is not forced to pick one style of heddle. With Leclerc looms they are free to pick the type they are comfortable with and can even switch later if they change their mind. This means they can choose Texsolv, Wire, Inserted Eye, Flat Steel and metal Repair Heddles and even mix all types on a single shaft if they want. They all fit! |

|

|

Back-Hinge Treadles (8 shaft only)

As the number of shafts on a loom increases, the amount of force required by the weaver to create the same sized shed in the warp increases. This is because each new shaft must lift and/or lower the warp threads a little more than the previous shaft so that it's warp threads are positioned parallel to the ones attached to the other shafts (ie. producing a "clean" shed). This means that as the number of shafts increase, there is also an increase in the force required by the weaver to depress the treadles with their feet.

The most basic solution to applying more force is the lever and Leclerc has utilized that concept in the Back-Hinge Treadle version of their looms. Instead of the weaver pushing down on a short treadle mounted to the front of the loom, a longer set of treadles that pivot at the back of the loom go under the lams and extend to the front of the loom, appearing like the foot pedals on an organ. When the weaver presses down on the extended treadles, they get a similar leverage action to help pull down the lams. This is similar (and upside down) to the leverage provided by the extended handles that make it easy for a person to lift a heavy object in a wheelbarrow.

For those who don't have a lot of lower body strength but want to weave with more than 4 shafts, the Leclerc "back-hinged" design increases the weavers leg leverage producing a wide, clean shed with much less effort than conventional front mounted treadles. The Back-Hinge Treadles are available on the 8 shaft versions of the Artisat and upgrades for older Artisat looms without the feature are available. See how Back-Hinge Treadles operate in the video here

Unlike other manufacturer's looms, Leclerc's Back-Hinge Treadle design incorporates a unique "Treadle Guide" which ensures that the treadles can only move up and down. The guide is a set of inverted "U" shaped rods rising from the bottom of the loom frame which prevent horizontal movement. This eliminates the problem of treadles swinging side to side causing the weaver to have to watch where their feet go to avoid missing the treadle or having their foot slip off. With the Leclerc system the weaver can concentrate on the pattern and throwing the shuttle!

A more detailed explanation can be found here: Back-Hinge Treadle Operation

|

|

|

Treadle Springs (8 shaft Jack only)

In some cases on a Jack loom where a large number of treadles are attached to a shaft, the weight can apply a force that may cause the shaft to rise when not required. This is commonly referred to as a Floating Shaft and a more detailed description of the problem can be found here.

To deal with Floating Shafts, the 8 shaft versions of the Artisat Jack loom have a set of springs on the back of the castle that can be connected to one or more treadles to counteract the downward force by applying a similar upward force. When the weaver depresses a treadle with an attached spring, the spring stretches to allow the treadle to go down. These springs are metal and much more durable then the elastics that some loom makers use for the same function. |

|

|

Quality Materials

Located in an area known for the production of Maple Syrup, Leclerc has access to high quality Maple Hardwood which is perfect for building sturdy but beautiful loom frames. The Artisat loom frame is made using high quality solid hard Maple beams and the wooden jack/lam/treadle/shaft mechanism is made of wood instead of the cord system some loom makers use to reduce costs. The strength incorporated into the design by using thicker and stronger frame parts can be readily seen by comparing the weight of the Artisat with similar competing models that use thinner frame members.

Custom metal parts are used in places like beam ends, brake and warp tensioning mechanisms, folding hinges and bracves, where large forces are applied or wear may occur. Durable non-sliding polyvinyl footpads are attached to the base of all the loom feet to reduce movement while protecting the floor. Nylon parts are only used where soft bumpers or glides are required.

A heavy duty canvas apron is provided for the cloth beam and a metal Beam Stick is used on the warp beam to reduce loom waste by letting the weaver use as much of the warp as possible. Heavy duty steel rods and the cords to attach them to the aprons are included.

Leclerc also includes a Boat Shuttle, Bobbins, a Reed/Heddle Hook, Heddles and a Steel Reed with the loom as well as assembly instructions and their basics guide to weaving called Warp and Weave.

The high quality materials used and the quality of the Leclerc design and construction are the reason that there are so many Artisat looms still in use around the world after decades of service!

|

|

|

More Value for the Money

As a North American loom manufacturer, Leclerc has the benefit of not having to add a second level of distribution between themselves and their retail stores. Most of the other loom manufacturers from outside the US and Canada, as well as having to add the price of International shipping and import costs to their looms, must also include the cost of a North American importer who buys from them, imports the looms and then sells them to the dealer adding another level of markup. This results in higher prices for the loom or less money being put into the materials used to make them affecting quality.

To get their prices down, some loom manufacturers remove items that then have to be purchased by the weaver separately. Some looms actually come with half the number of heddles that are required, don't include a boat shuttle (or replace it with a low cost stick shuttle) or don't include such basics as a reed/heddle hook.

Local manufacturing also means that parts, tools and accessories for Leclerc are fast and easy to get because dealers are not waiting for the North American distributor to have enough to order to justify the "next container" shipment. |

|

|

| Loom Version |

4 Shaft |

8 Shaft |

Ordering

Information |

Regular

Treadles |

1009-0000

$2,904 CDN

$2,671 US |

1009-0008

$4,111 CDN

$3,782 US |

Back-Hinge

Treadles |

N/A |

1009-3628

$4,174 CDN

$3,840 US |

| Heddles (#) |

1,000 |

| Width |

Weaving |

36" (90 cm) |

Overall Loom |

46" (117 cm) |

| Depth |

Open |

32" (80 cm) |

35" (89 cm)

42" (107 cm) for BHT |

| Folded |

14" (36 cm) |

17" (43 cm) |

| Height |

Loom |

44" (112 cm) |

| Front Beam |

30 3/4" (78 cm) |

| Weight |

95 lb (43 kg) |

135 lb (61 kg) |

- Email or call us at (519) 941-0736 for more information about this loom.

- Shipping to destinations within Canada or the Continental United States is included for this loom.

- Looms and accessories are guaranteed by Leclerc for one year covering defects in material and/or workmanship with parts replaced free of charge. Camilla Valley Farm extends this bringing it up to a full 2 year warranty.

- Looms are shipped partially disassembled for easier handling and to avoid damage during transit. Assembly is simple with both written and video instructions included as well as the required tools.

- Looms are made of selected, well-seasoned, kiln dried Canadian hard maple or birch, except for shaft frames and a few parts that require lighter wood. Metal parts are aluminium dye cast, cast iron and steel protected by metal zinc plating.

|

Double Warp Beam

The Double Warp Beam option is a designed to assist the weaver in situations where the take-up is greater on some warp threads than on others. This ofen occurs when mixing different types or thicknesses of yarn in the warp. The differing elasticity in a long warp of this fashion makes it difficult for the weaver to get an even tension on the warp threads. With two warp beams, the different yarn can be wound on the second beam and the weaver can control the tension independently.

The extra warp beam is easy to install with brackets on the back posts of the loom, and comes with it's own friction brake which can be operated by the weaver sitting at the loom. On floor looms, this feature eliminates the need for the weaver to get up and walk around to the back of the loom to release the tension to advance the warp.

The warp threads travelling to the second beam travel over a special secondary thread beam which mounts to the main thread beam and seperates the two warp threads. This beam and the mounting brackets for it are also included. The second warp beam is removable if not in use. (Note: Double Warp Beam pictured on Nilus model) |

|

|

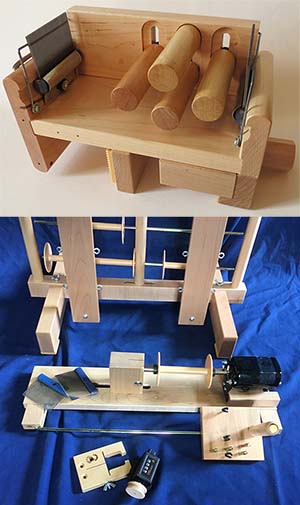

Sectional Warping Option

All Artisat looms have a 2 1/2 inch diameter Maple Warp Beam that is pre-drilled so that a set of 4 "rakes" can be added to allow the weaver to warp the loom sectionally. These Sectional Rakes are ordered as an option to the Canvas Apron that is included standard with all Artisat looms and comes in 1 or 2 inch spacing.

On a sectional beam, the warp can be wound up to the height of the metal clips. To allow for very, very long warps, a set of extensions can also be added to increase the beam diameter and as a result enable a much longer warp to be used. The Artisat warp beam has been positioned with enough space above and below to allow this expansion to occur.

In addition to the sectional beam a full Sectional Warping package can be provided including a Tension Box, Warp Counter, Spool Rack, Spools and Electric Winders. Leclerc also makes Dividers, Guides and a Tension Box Extension to help with winding.

While a new Artisat owner may not be interested in Sectional Weaving initially, it's nice to know that all the parts and tools are available from Leclerc to transition to this method of warping and that the loom is capable of being used this way. We often hear disappointment from customers who realize that this is not possible on other brands of looms! (Note: Sectional Beam pictured on Nilus model)I> |

|

|

Bench Options

Leclerc provides a number of bench options. All are made with the same high quality Maple Hardwood used in the looms and are finished with a simple varnish coating to match the loom.

The basic Fixed Height Bench (top right) provides storage for tools on either side as well as a larger storage area under the hinged seat. This bench has been designed with legs that allow it to be stored out of the way underneath the front breast beam and over the treadles when not in use.

An Adjustable Bench (top left) allows the weaver to set the height using removal bolts on each side and pre-drilled holes. Storage can be added to each side using optional canvas bench bags.

The Rocking Bench (bottom pictures) is also height adjustable but has a seat that can tilt slightly for comfort. The tilting action can be disabled using a removable bolt provided with the bench. Storage can be added to each side using optional canvas bench bags. |

|