Traditional Counterbalance looms operate most efficiently when used to weave a balanced weave. This occurs when each treadle connects to two shafts so when the treadle is depressed, two shafts come down and two shafts go up to form the shed. When the loom is tied for unbalanced weaves (ie. 3 shafts up/1 shaft down or 1 shaft up/3 shafts down) the shed is often smaller than the shed obtained with the balanced weave and/or requires the weaver to press harder on the treadles to get a good shed.

The Leclerc Shed Regulator mechanism that comes standard on looms like the Fanny II, Mira II and Nilus II Counterbalance removes this limitation. The Leclerc Shed Regulator is also available to upgrade older Mira, Fanny, M-Type and F-Type looms.

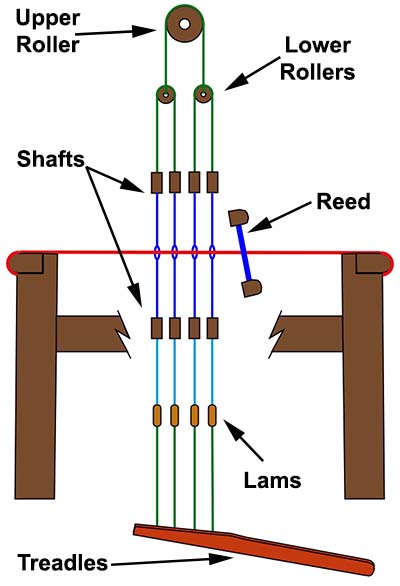

A traditional Counterbalance loom uses a set of rollers or pulleys mounted at the top of the loom to hang shafts from. They are set at a height so that the warp threads travel in a straight line between the front and back beam through the heddles and the center of the reed when the loom is at rest.

The treadles connect to a set of lams which are attached to the bottom of the shafts. Each treadle can be connected to one or more lam/shaft and when the treadle is depressed, it will pull those attached shafts downward. This action pulls down a group of warp threads that form the base of the shed as it comes out of the reed toward the front beam.

Because these downward moving shafts are connected to the other shafts via the roller cords and the pulley system at the top, the downward force of the shafts causes all the other shafts not attached to the downward moving treadle to rise up. This results in the remaining warp threads rising to form the top of the shed.

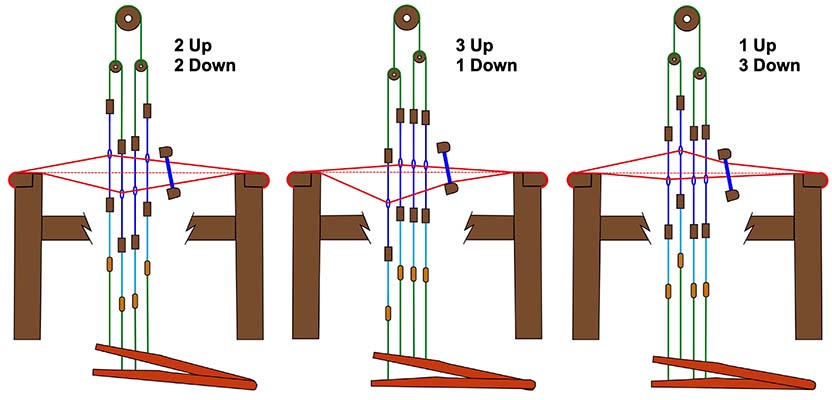

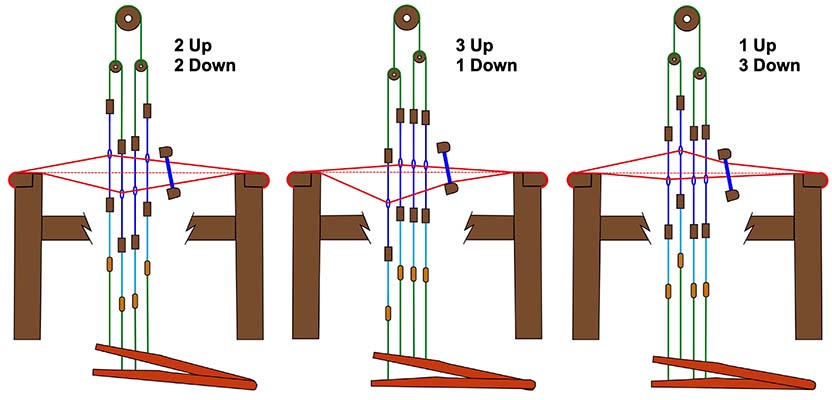

This works well for balanced weaves where two shafts move down and 2 shafts move up as shown in the leftmost picture below ("2 Up - 2 Down"). The balanced movement of shafts keeps the shed centered on the reed allowing its full height to be used.

When the tie-up for the loom is unbalanced, either one shaft or 3 shafts are connected to a treadle. As in the case of balanced weaves, depressing the treadle will cause the attached shafts to lower and the remaining shafts to rise. However, the warp threads for the one shaft moving in the opposite direction from the other 3 will move at a faster rate approaching the top or bottom of the reed sooner than the warp threads for the other 3 shafts will.

Once the warp threads hit the top or bottom of the reed the weaver will find the force required to continue depressing the treadle will increase as the threads will now have to follow a longer path as they bend around the reed. This makes it much harder for the weaver to expand the shed size further as they may not be able to increase the force on the treadle. Even if they do, only one set of warp threads will move to increase the shed size.

As the two pictures below to the right ("3 Up - 1 Down" and "1 Up - 3 Down") show, the actual center of the shed has moved up or down on the reed bringing it closer to the edge.

Some weavers may find they can apply the force required to get a usable shed, may find a smaller shed is acceptable, or may find that reducing the warp tension helps, but for many weavers, this limitation will affect their ability to weave or will find the extra force required uncomfortable. This force will also depend upon factors like the fabric width, the tension on the warp threads and the type of warp thread and how easily it stretches so some projects may be harder than others.

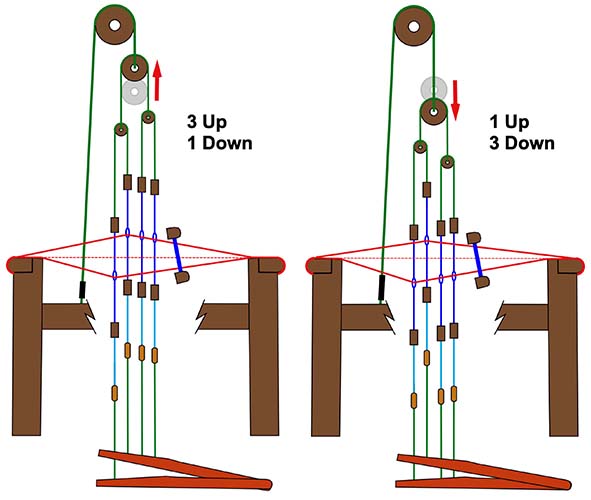

The basic problem with weaving unbalanced weaves on a Counterbalance loom is that the centre of the shed moves up and down in relation to the reed allowing the top or bottom of the reed to interfere with the shed size. With that in mind the solution is for the loom to A) first determine when the shed is moved away from the center, B) determine whether it is up or down and then C) have the loom simply raise and lower all the shafts to re-centre the shed on the reed. In this way, the top and the bottom of the reed are prevented from interfering with the shed size and it can expand.

This is what the Leclerc Shed Regulator, found on the Fanny II, Mira II and Nilus II Counterbalance looms, actually does. An additional roller added to the top of the loom is used to lift or lower the Counterbalance mechanism "upper roller" enough to allow the shed to expand to its full size depending upon which shafts are raised/lowered on that particular pick.

On older versions of the Shed Regulator, this raising and lowering had to be triggered with cords that connected the Shed Regulator mechanism to each of the treadles and took a bit of work for the weaver to set up each time they switched patterns. On the current improved version, a tension spring on a cord connecting the Shed Regulator mechanism to the loom frame, automatically senses the increase or decrease in force when the warp threads hit the top or bottom of the reed. Instead of making it harder for the weaver to depress the treadle, this tension triggers the Shed Regulator mechanism to move all the shafts up or down to allow the shed to continue to expand. The adjustment in the mechanism is fairly simple and involves shortening or lengthening the Shed Regulator tension cord when assembling the loom.

If the weaver wants the loom to operate as a standard Counterbalance loom, a locking pin can be inserted in the Shed Regulator roller to disable it.

The Shed Regulator comes standard on Leclerc Counterbalance looms or can be added to any older Mira, Fanny, M-Type or F-Type loom to improve their performance. Installation is simple with the brackets screwing into the same holes used by the Upper Roller Support. On older looms, instructions are provided to show where the two holes need to be drilled on each side.

Check out our Manual Section for downloadable assembly instructions for the Shad Regulator and other Leclerc looms and weaving accessories. Information is also provided on upgrades and accessories. If you are not sure which Leclerc loom you own see our Leclerc Loom Guide to help identify the model.

|

How to Order: Orders may be placed using our secure Online Order Form (this form should open in another window). Click Here for more information on how to place an order as well as our terms and conditions. Payment/Currency: Payment can be made using VISA or Mastercard, Cheque or Money Order in US or Canadian funds. US credit card purchases are billed directly in US funds eliminating any foreign currency conversion charges by the credit card company. Product Directories If you are looking for other items on our website, try using our product directories to quickly find what you are looking for! Our products are grouped as follows: Weaving/Spinning Product Index Books, Magazines & Videos. |

Price/Shipping Quote? If you would like an exact quote for any items complete with shipping costs, please call or email us at nmanners@camillavalleyfarm.com with you location and we will provide this. Gift Certificate If you are looking for a gift for a Knitter or Weaver and can't figure out what they want, a Camilla Valley Farm Gift Certificate is an excellent way to ensure you get the perfect gift! We can also email gift certificates if you are running out of time! Latest News/Updates Keep up to date with what is new at Camilla Valley Farm by following us on Instagram! (Click on the logo below)  |